EP-Steel-Clench-Rings and Cardboard Centers

| Steel-Clench-Ring-Type | Width | Inside Ø |

|---|---|---|

| K1 | 18 mm | 60 – 430 mm |

| K2 | 20 mm | 60 – 430 mm |

| K3 | 30 mm | 60 – 430 mm |

| MK | 10 mm | 14 hexagonal in mm |

| MN | 10 mm | 19 hexagonal in mm |

| MG | 10 mm | 19, 24 hexagonal in mm |

| MM | 15 mm | 19, 24, 32 hexagonal in mm |

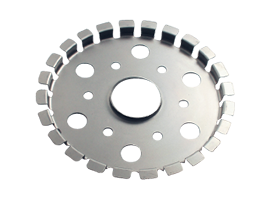

EP-Mounting-Flange K

To mount buffs with type K1, K2 or K3 clench rings with center plates

Single buffs or buff roller mounting must be supported on the side by a pair of correctly fitting flanges.

Available for all dimensions.

EP-Centering-Disc K

EP-Centering-Discs to mount type K1, K2 or K3 buffs or ring type centers.

Easily fitted in buff, sits firmly, most ecconomic means of centering, re-usable

single buff or buff roller mounting

exchangeable, environmentally friendly.

To be used with Mounting-Flange K.

– Ø 76, 130, 150, 178, 230, 430, 480 mm

– bores all

Precaution

Where buffs have a larger width on the outside circumference when compared with the width of the steel-clench-ring, cardboard spacers must be used to offset this difference in width. If this is not done, the steel-clench-ring could open.

e.g. Type C13/K

EP-Mounting-Flange B3 and B3/S

To mount Type B3 and Type B3/S

EP Abrasive-Flap-Wheels with ring type centers

– Every flap-wheel needs two flanges

– These flanges can be re-used

– Available for all spindle sizes