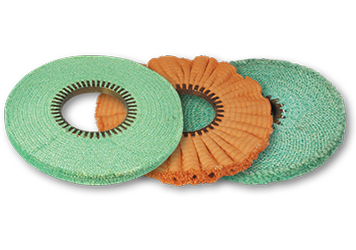

Sisal

By using only first class, long sisal fibers for matting and braid, the quality of the sisal polishing tools is exceptional and guarantees a long life.

Fine Grinding and Pre-Polishing

45° Degree Material Cut

Recommended Circumference Speed

Compounds

Suggestions for the Optimal Choice of Sisal Brushes

C1/K: hollow-ware, steel, inox steel

C10/K: hollow-ware pouring lips, cooking pots, fittings, household handles

C13/K: steel tubes, automobile parts, cooking pots

C20: hollow-ware, flat surfaces

More flexible brushes are used for profiled components, for example:

C3/KU: silver-polishing, cutlery in general

C4/KU: cutlery, metal sheeting, sinks

C8/K: cutlery, handles

C11/K: knife blades, paint-scrapers

Impregnations

The correct impregnation increases longevity of the buff and enhances the polishing effect. This in turn results in cost savings on polishing buffs and compounds. A 50-100% increase in longevity is possible. All our impregnations are environmentally friendly.

Through the years of experience and continuing innovation we have developed a number of exceptional impregnations, with varying properties: fat content, stickiness, softness or high density, as can be seen below.

| Impregnation | Colour | Application | Density |

|---|---|---|---|

| No. 1 | white | for aluminium-extrusions, steel | medium |

| No. 2E3** | red | steel, stainless steel | medium firm, very conformable |

| No. 3a | brown | steel, iron, stainless steel, silver | very soft and elastic |

| No. V10 | yellow | NF metals, iron, stainless steel | medium-hard |

| No. V10/80 | yellow | NF metals, iron, stainless steel | hard to very hard |

| No. V12 | orange | stainless steel | firm to hard |

| No. V122 | orange | stainless steel | firm to hard |

| No. V23* | lilac | stainless steel, chrome, nickel | medium, sticky, elastic |

| No. V25* | green | stainless steel, iron | very hard, aggressive |

| No. V28* | yellow | aluminium, stainless steel, steel | hard, aggressive |

| No. V31** | blue | aluminium, steel | medium soft, elastic |

| No. V33** | pink | aluminium, steel | medium, elastic |

| No. V33/HK** | pink | aluminium, steel | medium, elastic, sticky |

| No. V48 | darkblue | steel, stainless | very hard |