Type C1/K

EP-Sisal-Buff

Compact buff, stitched at 1 cm intervals, 45° sisal thread cut to minimize buff wear, in a steel-clench-ring (type K1 or K2). Compact pre-polishing buff, high stock removal, little dust formation

– Ø 150 – 980 mm

– width 12 – 22 mm

– ply 6 – 12

– stitching 5 mm or 10 mm intervals

Applications:

hollow-ware – outside and inside,

as single buff for zone areas e.g. pouring lip

as stacked buffs for flat surfaces of steel,

iron and non ferrous metals,

hand, automatic or robotic use

Type C1/K Mini

EP-Sisal-Buff

Compact buff stitched at 1 cm intervals, 45° sisal thread cut to minimize buff wear, in a steel-mini-clench-ring. Compact pre-polishing buff, high stock removal, little dust formation

– Ø 70 – 230 mm

– width 10 – 15 mm

– ply 4 – 6

– stitching 5 mm or 10 mm intervals

– bore 19/6, 24/6 or 32/6 hexagonal in mm

Application:

cutlery, hollow-ware,

profiles steel, iron and non ferrous metals;

hand, automatic or robotic use

Type C8/K

EP-Sisal-Cotton-Buff, open folding

Sisal and cotton cloth sewn together, cut at 45° to prevent wear, in a steel-clench-ring (type K1 or K2); light wavy and irregular folding enables the buff to work elastically, flexibly

– Ø 150 – 600 mm

– width appr. 20 mm

– ply 4

Applications:

aluminium profiles, flat surfaces,

tubes, cutlery contoured work pieces

hand, automatic or robotic use

Type C8/K Mini

EP-Sisal-Cotton-Buff, open folding

Sisal and cotton cloth sewn together, cut at 45° to prevent wear, in a steel-clench-ring; light wavy and irregular folding enables the buff to work elastically, flexibly

– Ø 70 – 250 mm

– width 10 – 15 mm

– ply 2 – 4

– bore 14/6, 19/6, 24/6 and 32/6 hexagonal in mm

Applications:

cutlery, hollow-ware, profiles

hand, automatic or robotic use

Type C10/K

EP-Sisal-Cotton-Buffs coarsly folded, compact buff

Sisal and cotton cloth sewn together, cut at 45°, in a steel clench-ring (K1 or K2), stitched, more pronounced folding than C8/K, therefore more robust in action, high stock removal, high longevity

– Ø 230 – 1000 mm

– width 22 – 25 mm

– stitching 1 cm intervals

Applications:

hollow-ware, flat work pieces, knives, pouring lips and base of cooking pots, flat electric irons,

automatic and robotic use

Type C11/K

EP-Sisal-Cotton-Buff, open coarse folding

Sisal and cotton cloth sewn together, cut at 45°, in a steel clenchring (K1 or K2), stitched, the polishing buff is particulary elastic and flexible due to it’s open folding pattern when compared to the C10/K, good stock removal

– Ø 230 – 1000 mm

Applications:

steel and knife making industry, knife blades,

automatic and robotic use, automatic buffing machines

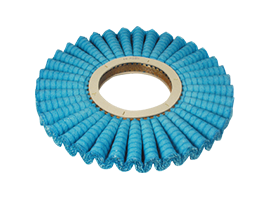

Type C13

EP-Corrugated-Sisal-Cotton-Buff

Sisal and cotton cloth sewn together, cut at 45°, in a steel clench ring (K1 or K2) or on a cardboard center, constant number of exact folds, strongest and most aggressive folding, exceptional qualities and longevity; the exact fold pattern allows buffs to fit into one another giving closed pre-polishing surface

– Ø normal density 300 – 430 mm dense and extra dense 400 – 600 mm

– width 25 mm

– density normal: C13, dense: C13/D, extra dense: C13/XD

Applications:

hollow-ware, cooking pots, stainless steel tubes,

flat pre-polishing. Gap- and lineless pre-polishing,

exceptional also as a single polishing buff on edges of items like flat electric irons, or cooking pots,

quick and effective pre-polishing on oscillating and not-oscillating automatic machinery

Type C2

EP-Sisal-Buff

Conventionally stamped from finely woven, full sisal discs. Sisal discs can be mixed with cotton to improve the life of the buff and polishing performance. Mainly used manually and on tapered spindles. The treads do not run at 45°, but at the standard 90°, which makes it softer. When ordering, please always indicate whether you require pure sisal or mixture of sisal and cotton

– Ø 50 – 500 mm

– width 4 – 25 mm

– stitching 0,5 cm narrow stitching or 1 cm normal interval stitching

Applications:

hand polishing

elastic, simple, universal use

manual work